3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

@ExtremeDullard

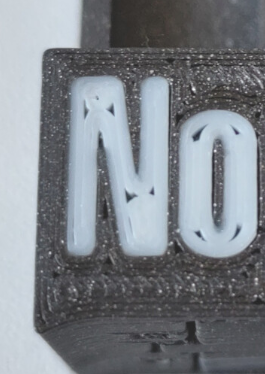

There is less material than needed all over the place, look at the not bonded perimeter lines on the top corner.

Measured the real filament diameter before printing and corrected the slicer settings to the measured diameter?

Are the extruder steps calibrated?

If iam to lazy to reslice, i would increase feedrate to around 106% and look at the following layers if the gaps are closed mid print.

This can be seen at layer 2 and corrected while printing

No and I don't even know how to do that 🙂 The printer is the company's Prusa XL and we're using it as it came out of the box. I'm normally very happy with what it churns out, it's just that small esthetic issue on a part that bears the company logo, that we intend to sell to customers.

I'll look into that. Thanks!